In today’s world of technology, 3D printers are becoming increasingly popular for their ability to create three-dimensional objects from digital designs.

Affordable Options for Every Budget

One of the most appealing aspects of 3D printers is the variety of models available at different price points. For beginners and those on a budget, there are entry-level printers priced under $300. These printers often have smaller build volumes but are perfect for learning the basics of 3D printing. Mid-range printers, typically priced between $300 and $1000, offer larger build volumes and more advanced features like touchscreen interfaces and Wi-Fi connectivity. They strike a good balance between affordability and functionality, making them suitable for both enthusiasts and small businesses.1

High-Quality Results

For professional-grade printers, which can range from $1000 to several thousand dollars, users can expect high precision, larger build sizes, and compatibility with a wider range of materials. These printers are ideal for industries such as engineering, architecture, and healthcare, where precision and reliability are crucial.

How to Choose the Right Model

Selecting the right 3D printer involves considering several key factors:

- Build Volume: This refers to the maximum size of the object that can be printed. Larger build volumes allow for printing bigger objects or multiple smaller objects simultaneously.

- Printing Technology: Common types include FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each technology has its advantages and is suited to different applications.

- Materials Compatibility: Check which types of filaments or resins the printer can use. Some printers are versatile and can handle a wide range of materials, while others are more limited.

- Ease of Use: Look for features like touchscreen interfaces, intuitive software, and straightforward calibration processes, especially if you’re new to 3D printing.

- Support and Community: Consider the availability of customer support, online forums, and tutorials. A strong community can be invaluable for troubleshooting and sharing tips.

- Reviews and Recommendations: Read reviews from other users to get insights into reliability, print quality, and overall satisfaction with the printer.

6 Benefits of Using a 3D Printer

1. Creativity and Customization: 3D printers allow users to bring their ideas to life by creating custom designs and prototypes. This is particularly useful for designers, artists, and engineers who need to visualize concepts.2

2. Rapid Prototyping: In fields like product development and manufacturing, 3D printing accelerates prototyping processes. Design iterations can be quickly tested and refined without the need for costly tooling.

3. Education and Learning: In classrooms, 3D printers are valuable tools for teaching STEM subjects. Students can engage in hands-on learning by designing and printing objects, enhancing their understanding of geometry, physics, and engineering principles.

4. Cost Efficiency: For small-scale production runs or one-off designs, 3D printing can be more cost-effective than traditional manufacturing methods. It reduces waste by only using the material needed for each object.

5. Accessibility: With affordable desktop printers, individuals and small businesses can access technology that was once exclusive to large corporations. This democratization of manufacturing capabilities fosters innovation and entrepreneurship.

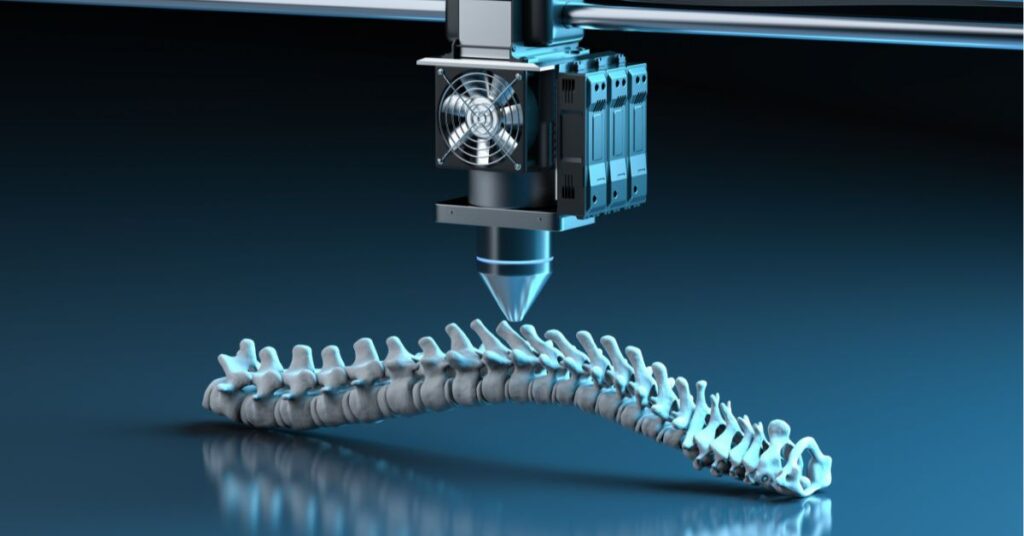

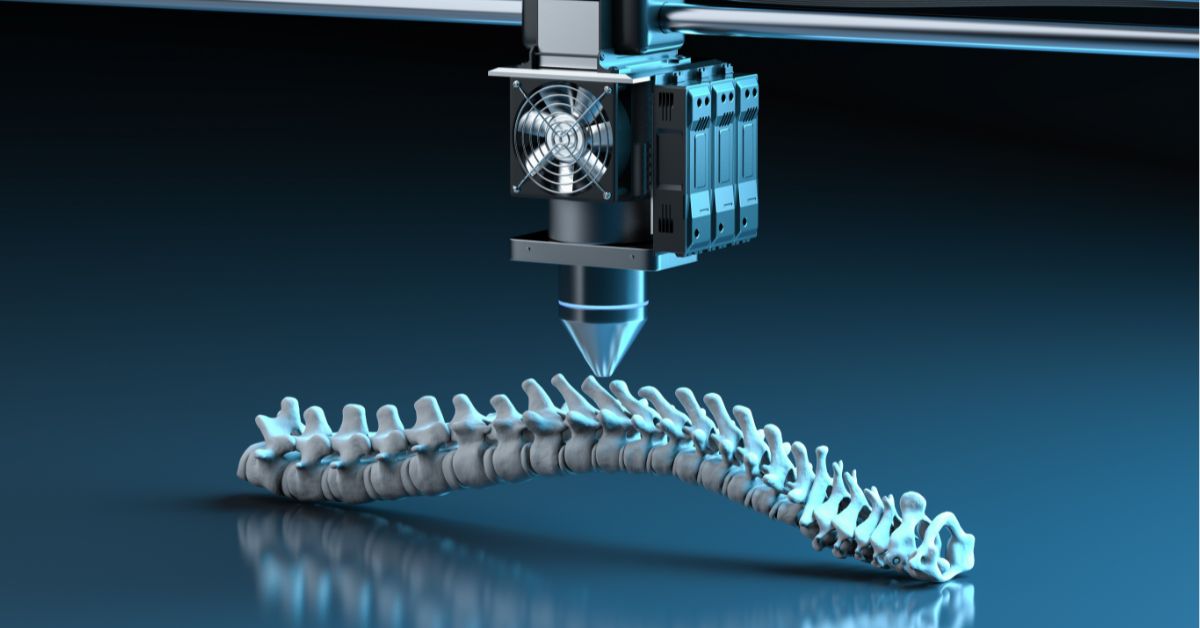

6. Personalized Healthcare: In medicine, 3D printing enables the creation of patient-specific implants, prosthetics, and anatomical models for surgical planning. This customization improves treatment outcomes and patient care.

Tips for Successful 3D Printing

Achieving successful 3D prints involves mastering several key aspects of the printing process. The following are some tips to help you get the best results from your 3D printer:

1. Calibration is Key

Proper calibration ensures that your 3D printer operates accurately and efficiently. This includes calibrating the bed leveling, extruder, and overall machine geometry. Many printers come with calibration guides or automated calibration features that simplify this process. Regular calibration prevents issues like uneven prints or adhesion problems.

2. Choose the Right Filament

The type of filament you use significantly impacts print quality and durability. Common filaments include PLA, ABS, PETG, and TPU, each with its own strengths and ideal printing conditions. Consider factors like material properties, print temperature range, and post-processing requirements when selecting filament for your project.3

3. Understand and Adjust Print Settings

Familiarize yourself with your printer’s settings such as print speed, layer height, temperature, and infill density. These settings can affect print quality, strength, and the overall success of your prints. Start with recommended settings for your filament and adjust based on the specific requirements of each print.

4. Ensure Proper Adhesion

Proper adhesion between the print and the build surface (usually a heated bed or print surface) is crucial for preventing warping and ensuring the print stays securely in place throughout the process. Techniques for improving adhesion include using adhesion aids like glue sticks, painter’s tape, or specialized bed adhesives. Experiment with different methods to find what works best for your printer and filament.

5. Use Supports Wisely

Supports are structures that help uphold overhangs and complex geometries during printing. While supports are essential for some designs, they can also affect surface finish and require additional post-processing. Use slicer software to generate supports only where necessary, and consider their placement and density to minimize their impact on the final print.

6. Monitor the Print

Stay vigilant during the printing process to catch potential issues early. Watch for problems such as filament jams, layer shifting, or adhesion failures. Many modern printers offer remote monitoring options via smartphone apps or web interfaces, allowing you to keep an eye on your print even when you’re not physically present.

7. Post-Processing for Finishing Touches

After printing, post-processing can enhance the appearance and functionality of your prints. Techniques such as sanding, painting, or applying surface treatments can smooth rough edges, improve surface quality, and add color or texture. Consider the intended use of the printed object when planning your post-processing steps.

8. Learn from Others

Take advantage of online communities, forums, and maker spaces where experienced users share tips, troubleshooting advice, and innovative techniques. Learning from others’ experiences can help you avoid common pitfalls and discover new ways to optimize your 3D printing workflow.

9. Keep Your Printer Well-Maintained

Regular maintenance helps extend the lifespan of your 3D printer and ensures consistent performance. This includes cleaning the build plate, lubricating moving parts, checking belts and pulleys for tension, and periodically replacing consumable parts like nozzles or build surfaces. Refer to your printer’s manual for specific maintenance guidelines.

10. Experiment and Iterate

3D printing is a learning process, and experimentation is key to improving your skills. Don’t be afraid to try new settings, materials, or design techniques. Keep a record of your settings and results to track your progress and identify what works best for different types of prints.

By following these tips and investing time in mastering your printer and materials, you can achieve high-quality 3D prints consistently. Each print brings new opportunities to refine your techniques and unleash your creativity in the world of additive manufacturing.

Find 3D Printing Technology Now

As 3D printing technology continues to evolve, its applications across various industries and disciplines are expanding. Whether for educational purposes, artistic endeavors, or professional projects, choosing the right 3D printer involves understanding your specific needs and the capabilities of different models. With the right knowledge and equipment, anyone can unlock the creative potential of 3D printing and bring their ideas into the physical world. To see cheap 3D printers, start an online search now.

References:

- https://www.cnet.com/tech/computing/best-budget-3d-printer/

- https://fastercapital.com/questions/how-3d-printing-startups-are-empowering-artists-and-designers:unleashing-design-possibilities:-from-concept-to-reality.html

- https://formlabs.com/asia/blog/fdm-vs-sla-vs-sls-how-to-choose-the-right-3d-printing-technology/

Leave a Reply